Three weaving methods for decorative stainless steel mesh:

(1) Plain weave

Plain weave is the most simple, common and common weaving method in which the warp and weft threads are interwoven up and down once every other thread, that is, the warp and weft threads are intertwined one up and down.

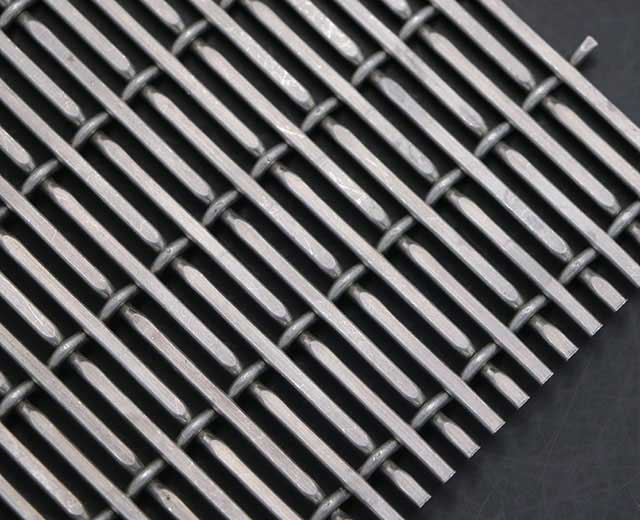

(2) Twill weave

The characteristic of twill weaving is that the warp or weft interlacing points continuously form a sagittal twill loop on the mesh surface, and there must be at least 3 warp threads and 3 weft threads, both of which are indispensable. If the twill line is inclined from the lower right to the upper left, it is called left twill; if the twill line is inclined from the lower left to the upper right, it is called right twill.

(3) Satin weave

Satin weaving is a more complicated weaving process, and its main feature is that the interlacing points are not continuous, but evenly and sparsely distributed in a circulating tissue. Its interweaving parameter R is greater than or equal to 5, that is, the number of warp or weft threads in a weave loop of the interweaving point of the satin mesh should be at least 5, and the number of interlacing points S (the number of interlacing points is called the number of interweaving points) is the same as the number of interwoven points. The values of R are not integer multiples of each other and cannot have a common pisor, otherwise the distribution of the interleaving points will be uneven.

© 2025 Joinwin Architectural Wire. All Rights Reserved. | Sitemap

Recommended Read

Maintenance and care methods of architectural decorative metal mesh

Metal coil drapery is created by weaving metal coils