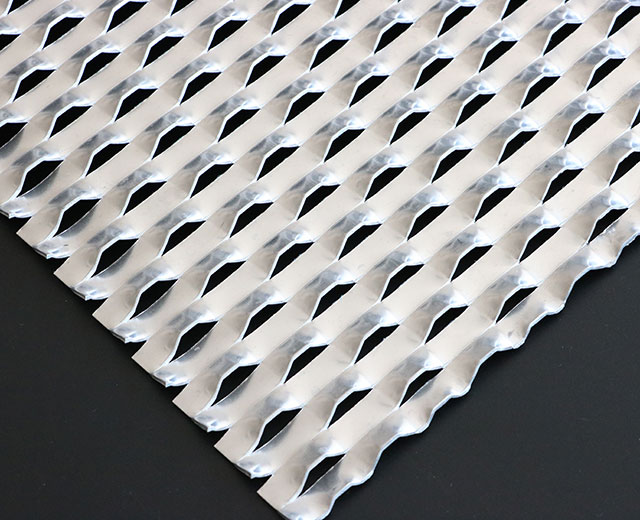

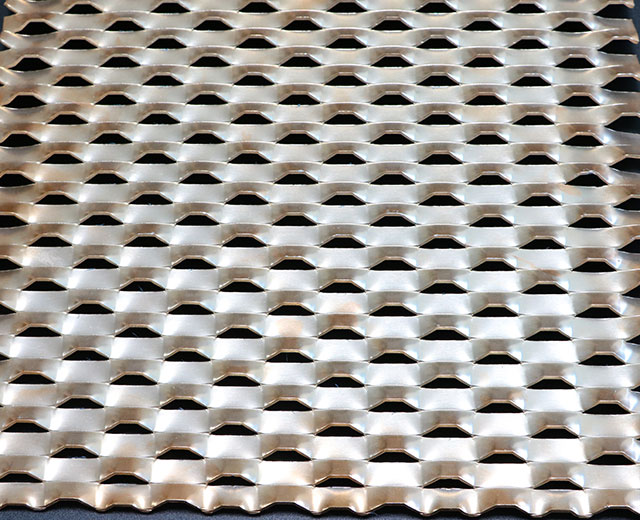

Pay attention to the cutting angle and cutting fillet when processing expanded metal. This will make the appearance of the product beautiful and also make it practical. For example, when it is used in pipes, a circle must be cut. This will make the arc more suitable for the shape of the tube, thereby prolonging the use time. Cutting process can make the load-bearing capacity stronger, and the angle after cutting can also be trimmed, such as using angle steel or flat steel edge to stabilize the structure of the expanded metal.

The role of the metal mesh: decorative ceilings are mainly used for the protection and deployment of bulk cement in civil buildings, complete sets of equipment, handicrafts, and speaker nets. Protective nets for highway guardrails, sports fences, and road green belts. Heavy expanded steel mesh can be used for tanker pedal nets, heavy machinery and boilers, oil mines, locomotives, 10,000-ton ship platforms, escalators, sidewalks, etc., and can also be used for steelmaking, highways and bridges in the construction industry.

1. The plate is not fixed properly, causing uneven force and deformation during the stamping and drawing process.

2. The degree of wear of the metal mesh machine mold is too high, and it cannot work normally, resulting in deformation.

3. The tensile strength of the expanded metal machine is insufficient when punching, and the thickness of the steel plate is too large, which causes the expanded metal machine to not work normally.

4. the quality of the selected steel plate is too poor.

pre:Electrolytic polishing of metal decorative mesh curtains.

next:Three weaving methods for decorative stainless steel mesh

© 2025 Joinwin Architectural Wire. All Rights Reserved. | Sitemap

Recommended Read

Step-by-Step Installation: Mastering the Technique of Expanded Metal Facade Cladding

Beyond the Surface: How Expanded Metal Facade Cladding Enhances Building Exteriors