What is the purpose of wired glass mesh?

(1) According to the commonly used diagrams, wired glass is used for fire protection. First of all, when cutting general glass, the cut is easy to break. The strength of the notch is about half that of laminated glass, so it is more prone to thermal cracking than laminated glass.

(2) The wire mesh surface of the laminated glass is specially treated, and it is generally not easy to rust. The cutable part is in an unprocessed state, so it sometimes rusts when exposed to water. In severe cases, the volume expansion can cause the cut to break down, thereby reducing the strength of the edge. This is the cause of thermal cracking.

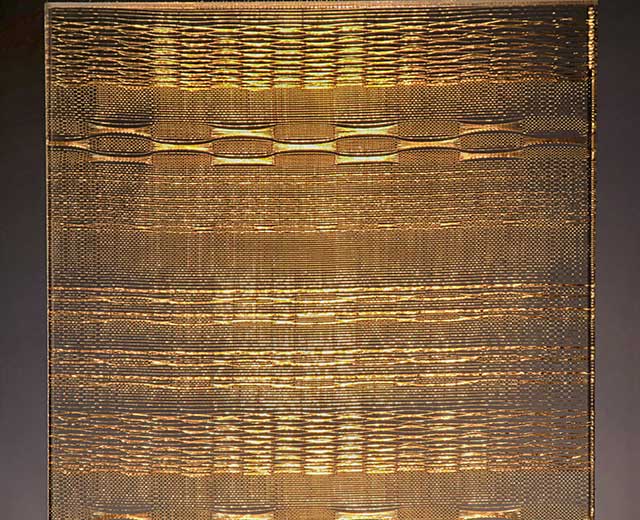

Production process: Wired glass is a kind of safety glass produced by calendering process. After the web is unrolled, the molten glass is sent into the molten glass, and the molten glass is pressed up and down together to form the laminated glass. The wire frame lattice shape of laminated glass is usually square or hexagon, and the surface of the glass is patterned or shiny. The thickness of laminated glass is generally 6-16mm (thickness without intermediate wires), and safety glass can be used for building ceilings, etc.

pre:What are the reasons that affect the process of Decorative P

next:Electrolytic polishing of metal decorative mesh curtains.

© 2025 Joinwin Architectural Wire. All Rights Reserved. | Sitemap

Recommended Read

Luxury Chain Link Curtains for Southeast Asia – Premium Decorative Wire Mesh Manufacturer from China

Decorative ceilings – a new choice to enhance the beauty and function of the space