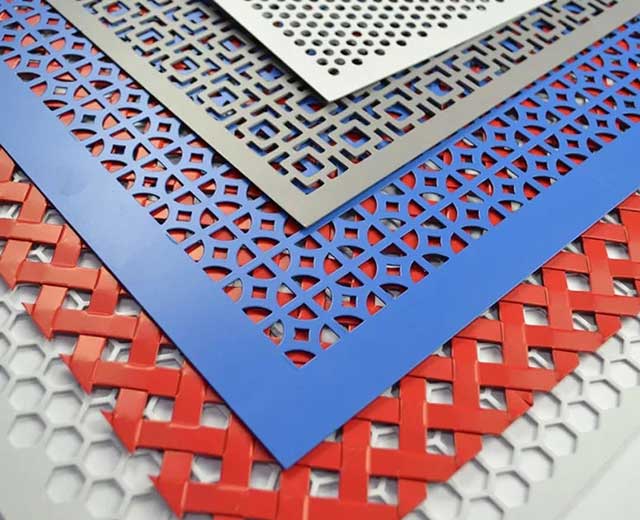

Perforated mesh products can be said to be very common products in our daily lives. Whether it is used for environmental protection or decoration, there are perforated mesh products. Especially in recent years, they have been widely used in theaters, concert halls and other places, and only need to punch different types of holes to meet various environmental needs.

For punching mesh products, we know that it stops punching on the plate, and it will deform to varying degrees after processing, and some even become cylindrical, but what is the reason for the thinness? Some customers may not know too well, so I will solve this mystery for everyone today.

Material: Different materials have different degrees of deformation after stamping. The degree of deformation of stainless steel is also difficult to reach the level. This is because stainless steel has good rigidity and certain toughness. The same flatness as before.

Aperture and pitch: the smaller the hole, the denser the spacing, and the worse the flatness. The punching process of the punching needle and the stainless steel plate is equivalent to applying force to the stainless steel plate during CNC punching, which will make the plate hard and not good in drawing.

Keep margins: The larger the margins, the worse the flatness, especially the larger the opening rate, the larger the aperture, and the larger the four margins, it is particularly difficult to level, but don’t worry, we have professional leveling equipment, we will try to level the board as much as possible. , Convenient for customers to use.

In order to ensure a better product, the leveling must be stopped after the punching plate is processed. The so-called leveling refers to the use of leveling machines and other equipment to restore the punched meshes to their original flat state after being punched by numerical control. Moreover, it is usually necessary to clean the punching net after leveling. During this period, a lubricant will be used to stop the treatment to make the CNC punching plate cleaner.

© 2025 Joinwin Architectural Wire. All Rights Reserved. | Sitemap

Recommended Read

Luxury Chain Link Curtains for Southeast Asia – Premium Decorative Wire Mesh Manufacturer from China

Decorative ceilings – a new choice to enhance the beauty and function of the space