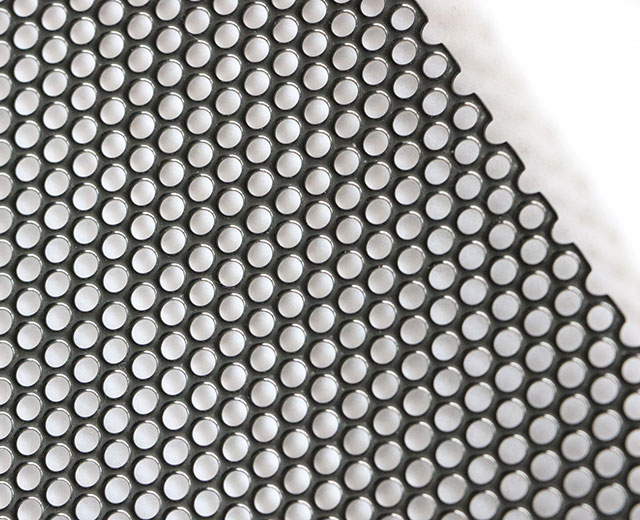

decorative perforated mesh essentials: continuous punching in the same direction: using rectangular perforated mesh molds to partially overlap the processing essentials, long holes, trimming, etc. can be processed. Continuous forming: the standard of forming and processing methods larger than the perforated mesh mold, such as large standard blinds, rolling ribs, rolling steps and other processing perforated mesh methods. Whale swallowing: Use a small round die to continuously punch out the arc-shaped processing method with smaller steps. Multi-directional continuous perforated: the processing essentials of using a small perforated mesh mold to process large holes. Single molding: the processing essentials for shallow deep drawing molding according to the shape of the mold. Single perforated: single-pass end punching, including straight-line diffusion, arc diffusion, circular diffusion, and mesh hole perforated. Array forming: the processing essentials for processing multiple communication or pergent workpieces on a large board.

Defect correction: misalignment caused by decorative perforated netting when perforating. Correction: When punching, due to the dissatisfaction of the anvil surface, the two ends of the perforated are skewed, the blank is heated unevenly, and the hole diameter is misaligned. The correction method can be carried out by immersion method: during operation, the thin wall of the hole is immersed in water to reduce the temperature, and then the hole is enlarged with a punch. Due to the higher temperature, good plasticity, and thinning of the thick wall, the wall thickness of all forgings is symmetrical, and the migraine is corrected. This method is suitable for materials with better plasticity. The blank is deformed when the decorative punching net is perforated. That is, the metal above the punch is squeezed around, the height of the blank is reduced, the diameter is increased, the upper end surface is recessed, and the lower end surface is convex.

© 2025 Joinwin Architectural Wire. All Rights Reserved. | Sitemap

Recommended Read

Decorative ceilings – a new choice to enhance the beauty and function of the space

Enhancing Modern Architecture with Architectural Decorative Mesh