Metal glass wire is more and more widely used. If we want to understand its characteristics, we need to understand what its production process is. So qunkun metal will explain to you the production process of metal glass wire mesh .

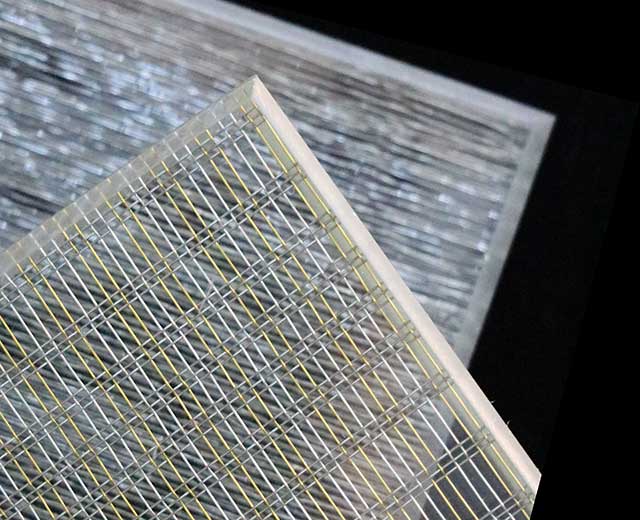

The metal glass clamp seems to be a kind of safety glass produced by the calendering process. The rolled metal wire mesh is unrolled by the mesh supply device and sent to the molten glass, and then passes through the upper and lower calendering rollers together with the glass to make wire glass.

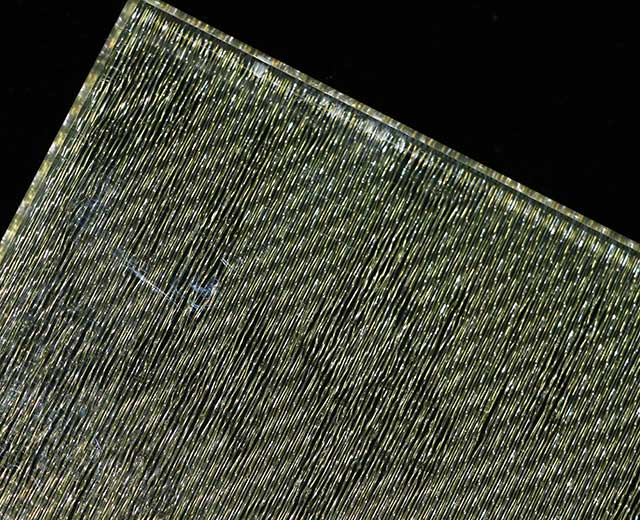

The wire mesh grid shape in the wire glass is generally square or hexagon, and the glass surface can be patterned or smooth. The thickness of the wire glass is generally 6-16mm (excluding the thickness of the intermediate wire). Wired glass is made of metal wire mesh and metal wire, which are pided into ordinary steel wire and special steel wire. The diameter of ordinary steel wire is 0.4mm or more, and the allowable deviation of length and width is ±4.0mm. Through the above steps, the metal glass sandwich screen can be completely produced. Of course, the production requirements are also perse, which can be met according to customer requirements.

pre:Introduction of technical parameters for the production of c

© 2024 Joinwin Architectural Wire. All Rights Reserved.

Recommended Read

In-depth introduction to metal mesh curtains

Explore the charm and application prospects of architectural decorative wire mesh