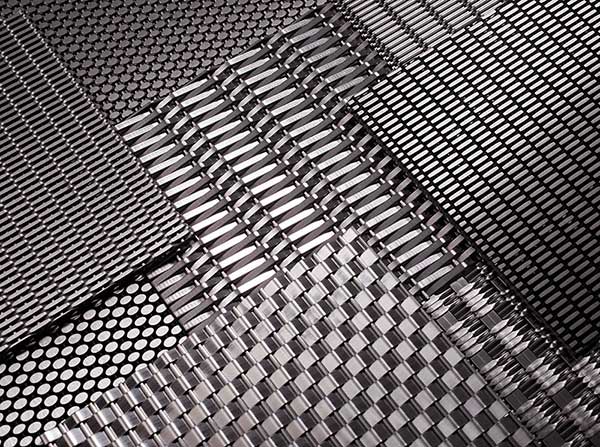

Introduction of technical parameters for the production of crimped wire mesh

1. Crimped mesh quality defects, wrong size, irregular warp and weft, uneven mesh surface, mesh surface too loose, mesh surface too tight, mesh exceeding standard, short jumper.

2. The mesh error is allowed to be used within ±0.03mm.

Example: Use a wire with a wire diameter of 4.11mm, and the actual diameter is between 4.08mm and 4.14mm.

3. If the actual mesh is between ±3%, it is qualified

Example: The mesh size is 12.7mm, then the actual mesh is allowed to pass between 12.7×(1-3%)mm and 12.7×(1±3%)mm, that is, between 12.32mm and 13.08mm.

4. Diagonal error

(1) For narrow-length and wide-length meshes, the allowable diagonal error is between 0-12mm

(2) For narrow and short meshes, wide and short meshes, the allowable diagonal error is between 0-9mm.

5. Mesh wire head length

(1) For meshes with a wire diameter between 4.11mm and 11.1mm, the length of the weft wire head is greater than the wire diameter and less than one-half of the mesh.

For example (5.26, 25.4) mesh, the length of the wire head should be between 5.26mm and 12.7mm

6. Judgement of mesh tightness

It is appropriate to pinch the head of the weft wire to ensure that the weft wire slides on the side wire but does not slide on the second diameter wire. If it does not move at the side wire, the mesh surface is too tight.

7. Solutions to common problems of mesh

(1) If the mesh is tight as a whole (the mesh is not flat), the height of the deep weft must be rolled.

(2) In the process of weaving the net, moving forward on the other side of the net increases the pressure of the pressure plate on that side (compression screw)

(3) If the tightness of the two sides of the mesh is different, then which side of the mesh is loose, reduce the pressure of the pressure plate on that side (compression screw).

© 2024 Joinwin Architectural Wire. All Rights Reserved.

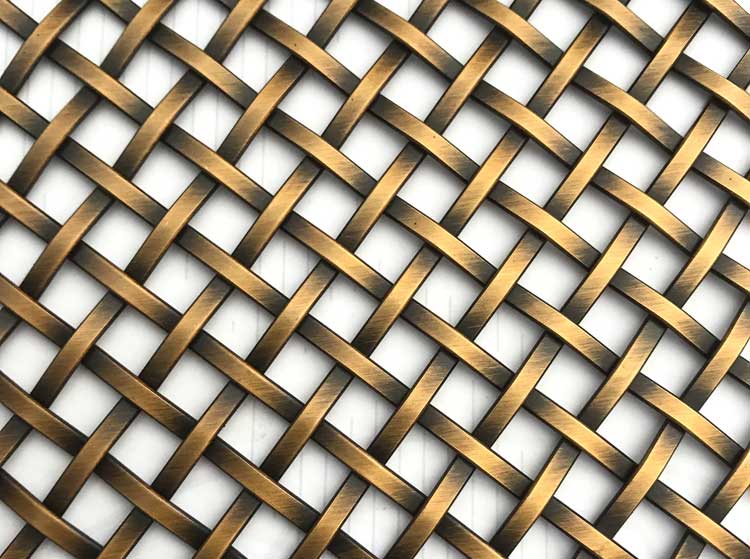

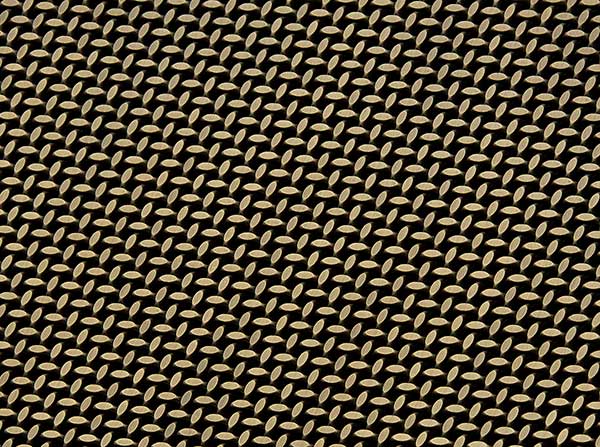

Recommended Read

In-depth introduction to metal mesh curtains

In-depth introduction of metal decorative mesh