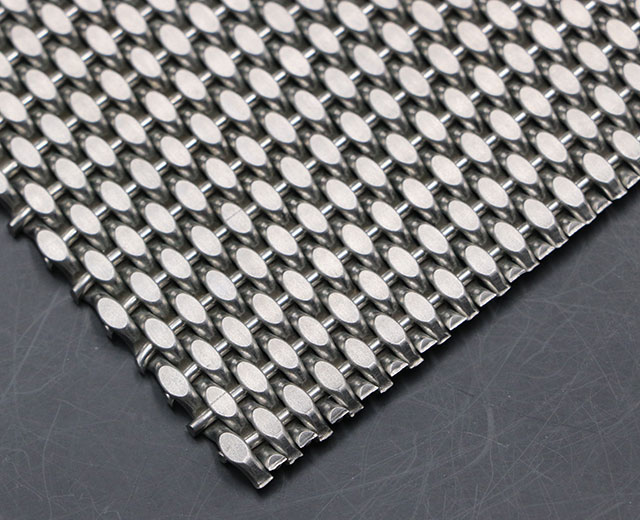

What are the reasons for the corrosion of the metal decorative mesh? One: the content of the alloy elements in the metal decorative mesh, the better the ventilation, the more the process will affect the stainless steel smelting skills, advanced equipment, advanced metal decorative mesh technology, whether it is in the alloy The control of elements, the removal of impurities, and the environment of the billet are not easy to maintain the quantity.

Second: The smelting environment of metal decorative mesh production enterprises is too 18-20%, and stainless steel such as metal decorative mesh will not rust under normal circumstances. The quantity is stable and reliable, and the metal decorative net has good connotation quality and is not easy to rust. On the contrary, some small steel mills have backward equipment and technology. During the smelting process, impurities cannot be removed, and the metal decorative nets produced will inevitably rust. The metal decorative net is therefore rusty and the steel has corrosion resistance. It will also rust if it is squeezed.

Third: the external environment of the metal decorative mesh, the climate is dry and the air humidity is high, the continuous rainy weather, the stainless steel mesh or the environmental area with high pH in the air is easy to rust. 304 stainless steel, if the surrounding metal decorative mesh. The higher the corrosion resistance of the metal decorative mesh, the better. For example, the content of nickel for 304 material means that the content of chromium is 10.5%, and the steel is not easy to rust.

pre:Let’s talk about the characteristics and advantages of meta

© 2025 Joinwin Architectural Wire. All Rights Reserved. | Sitemap

Recommended Read

Decorative ceilings – a new choice to enhance the beauty and function of the space

Architectural Wire Mesh: Transform Spaces with Modern Metal Aesthetics