The joint of the metal mesh belt can adopt mechanical joints, cold bonding joints and hot vulcanization joints according to the needs. Generally, cold-bonded joints and hot-vulcanized joints adopt stepped structure joints. So what are the commonly used methods when operating joints?

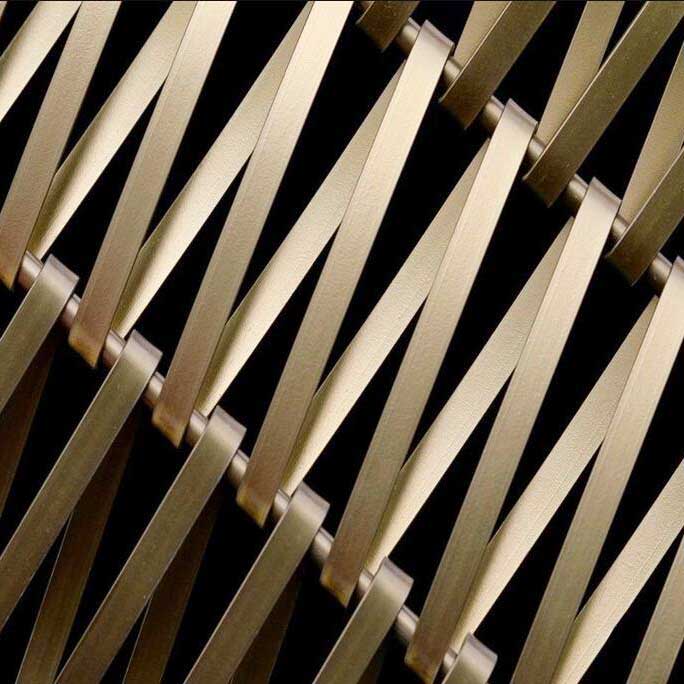

There are many common ways of connecting the metal mesh belt, such as mechanical equipment connection, cold bonding connection, and hot vulcanized rubber connection. Mechanical equipment connectors generally refer to the use of belt buckle connectors. This type of connector method saves time and effort, but the connector has low efficiency and is very easy to be destroyed. The service life of the metal mesh belt has certain hazards.

Cold-bonding joints is to use cold-bonding adhesives to develop the joints. This type of connector method is more efficient than mechanical equipment connectors, and should have a better actual effect of the connector, but from the perspective of practical activities, because the processing technology standards are more difficult to grasp, and the quality of the adhesive is harmful to the connector It's very large, so it's not very smooth.

The hot vulcanized rubber connector can ensure a high connector and high efficiency, and it is also very stable, and the connector has a long service life, which is very easy and easy to grasp. However, there are disadvantages such as inconvenience of processing technology, high cost, and long actual operation time of the connector. Most of the hand-made connectors refer to the connectors of the stainless steel mesh belt, because the stainless steel mesh belt is sometimes longer, so temporary connectors are used to facilitate the removal of the stainless steel mesh belt.

The connection head of the layered metal mesh belt can be selected according to the connection head of mechanical equipment, cold bonding connection and hot vulcanized rubber connection. Generally, cold-bonded connectors and hot-vulcanized rubber connectors use stepped structure connectors.

Because the structure of the whole core belt is relatively unique, the connection head is not very easy, so most of them choose the foot-type connection method, that is, the belt buckle connection head. However, for straps above level 8, in order to ensure the actual effect of the connector, the hot vulcanized rubber connector is generally used. The structure of the connector is all finger connectors. PVC and PVG flame-retardant conveyor belt flame-retardant metal mesh belt hot vulcanized rubber connector processing technology is very complicated, and the requirements for machinery and equipment are relatively high.

The connector of the galvanized steel wire rope core metal mesh belt is more technical than all metal mesh belt connectors, not only the processing technology is very complicated, but the main parameters of the connector specifications of the designed scheme are also the most numerous. The stainless steel mesh belt connector is classified according to the stainless steel conveyor belt, and the connector is different. The stainless steel conveyor belt has a net weight and a longer length. It is more suitable to use a temporary connector member. There are many ways to connect the metal mesh belt.

pre:What are the advantages and functions of metal mesh belts?

next:What are the parameters of the metal mesh belt high temperat

© 2025 Joinwin Architectural Wire. All Rights Reserved. | Sitemap

Recommended Read

Decorative ceilings – a new choice to enhance the beauty and function of the space

Architectural Wire Mesh: Transform Spaces with Modern Metal Aesthetics