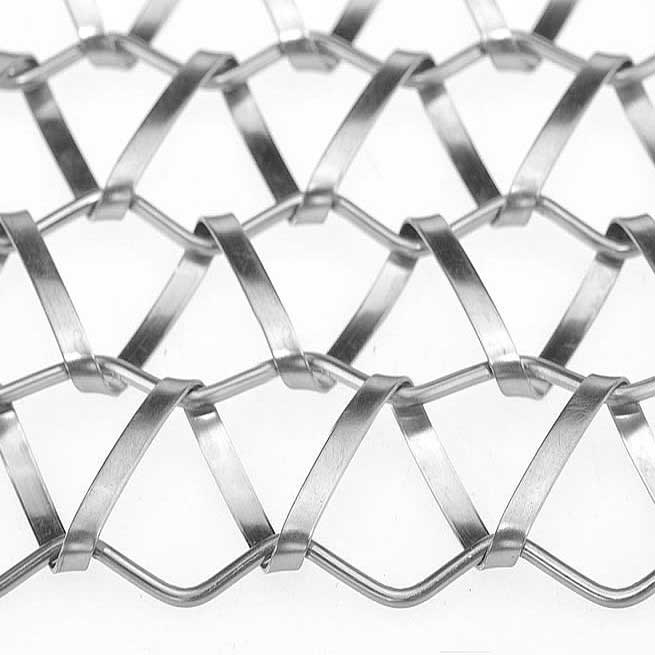

The friction drive of the general conveyor mesh belt uses the same method, like the more threaded support, if this method is used to adjust the support wheel and the drive wheel to keep parallel. So what are the two operating modes of the metal mesh belt?

1. Transmission gear

Advantage: It can ensure that the metal mesh belt is in a line and the drive is carried out. The operation of the conveyor belt and other practical operations can be done at the same time. Application places: Generally used in natural environments such as relatively light load-bearing and short furnace walls. Sprocket chain selection: When the driving sprocket and the conveyor belt touch each part, in order to avoid excessive ground stress and prevent distortion, the size of the suitable size should be selected. The driven sprocket and the other sprocket chain should be selected in the same size as much as possible.

2. Friction drive system

Features: better than the gear transmission method, so the driving force in this situation is not caused by the teeth and the force bone, but the drive is based on the friction between the roller and the Great Wall mesh belt surface. Therefore, the drive roller should be a large-diameter roller that can consider the design of the conveyor belt itself.

Application places: A, when the load is large, B, the temperature is high, and the conveyor belt is stretched. Use the same method as the ordinary stainless steel mesh belt friction drive, such as the use of more external threaded support points, if you choose this method to adjust, the support point wheel and the driving wheel should be kept parallel.

pre:What is the production process of stainless steel mesh belt

next:What is the unloading and stacking capacity of the transmiss

© 2025 Joinwin Architectural Wire. All Rights Reserved. | Sitemap

Recommended Read

Decorative ceilings – a new choice to enhance the beauty and function of the space

Architectural Wire Mesh: Transform Spaces with Modern Metal Aesthetics