2021-03-11

1. Metal wire drawing: use various metal wires from Ø6, 8, 10mm wire rod, after many times

Vacuum annealing, bright annealing, and drawing to the finest wire diameter 0.018mm finished wire.

2. Wire inspection: a spectrometer with an accuracy of 0.001mm micrometer and high-precision drawing is required

Force testing machine and other equipment testing.

3. Full diameter: tens of thousands of metal wires (up to 25,000) are evenly and evenly wound on the warp

On the axis.

4. Passing healds and reeds: pass each thread into each heald and each reed in an orderly manner

Inside.

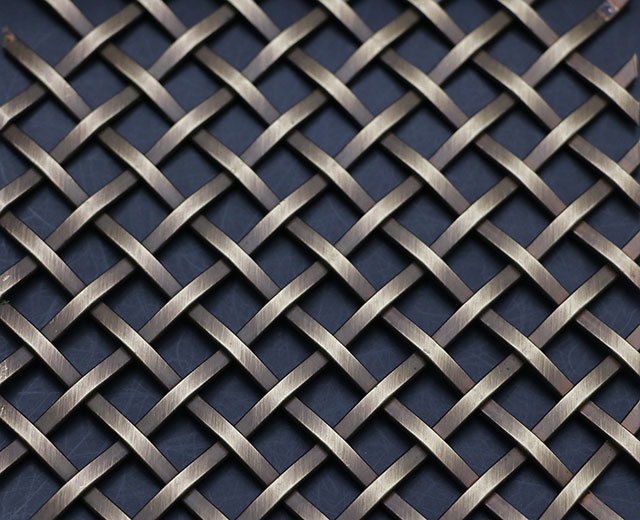

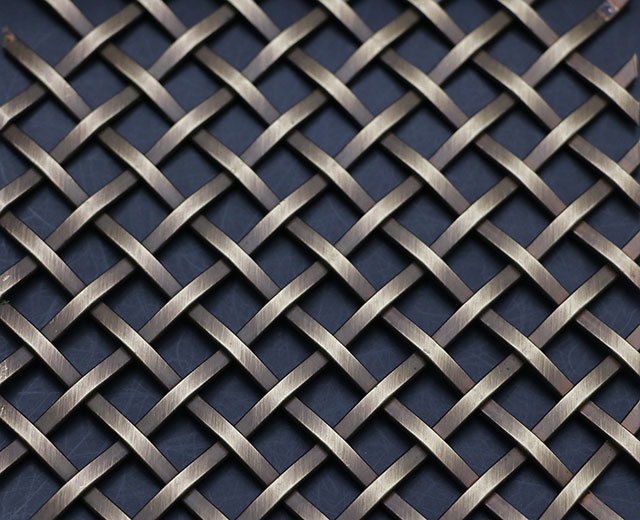

5. Adjusting the machine and weaving the net: it has to go through dozens of processes of lifting, helping, adjusting, weaving, and removing the net.

Can weave metal wires two or three times thinner than human hair into a way that there is no outside world

Metal wire mesh that does not leak even water under pressure.

6. Metal mesh inspection: use a micrometer, thickness gauge, tensile machine, 25 times magnifying glass, etc.

Instrument inspection.

Recommended Read

Architectural Decorative Mesh – A Fusion of Strength and Design for Modern Architecture

Luxury Chain Link Curtains for Southeast Asia – Premium Decorative Wire Mesh Manufacturer from China