2021-02-23

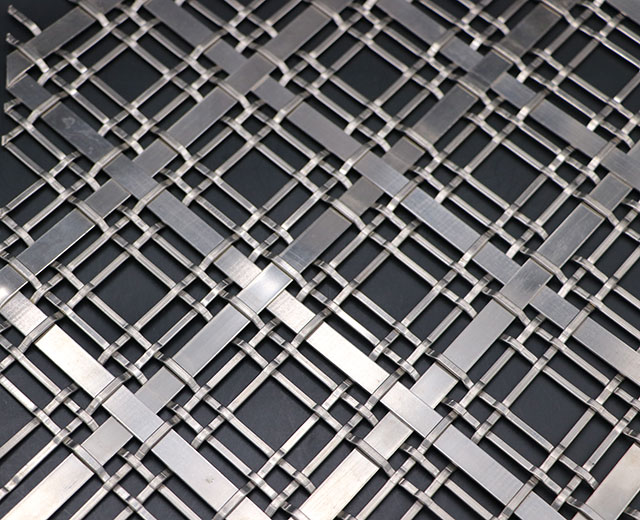

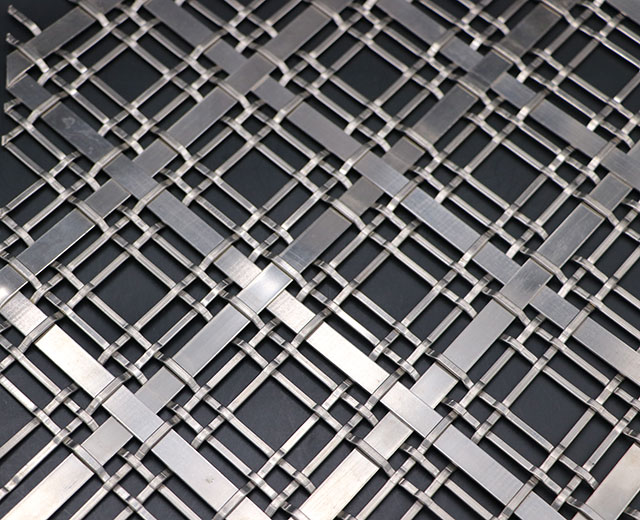

Stainless steel, stainless steel is generally made by adding nickel (Ni), chromium (Cr) and other metal alloy elements to steel. It is divided into different trademarks according to the added amount of various elements, which is suitable for different use requirements; according to its metallography The organization can be divided into two categories: austenite and ferrite (commonly known as stainless steel and stainless iron).

In order to strengthen the atmospheric corrosion resistance and suitable for outdoor use in construction, the elements chromium (Cr) and molybdenum (Mo) can be added to the stainless steel, which can greatly improve the atmospheric corrosion resistance Cr+3Mo as the corrosion resistance index of stainless steel. Is the pitting index. When compared under the same pitting index, the atmospheric corrosion resistance of the ferritic system is better than that of austenite and increases. When the content of Cr and Mo improves the atmospheric corrosion resistance, the cost of the ferritic system is also much superior.

Metal aluminum has its own uniqueness in anti-corrosion: the metal will quickly form a dense and thick aluminum oxide film in the air. The rapid formation of this aluminum oxide film prevents further corrosion. The difference from the appearance of anti-corrosion is that after this aluminum oxide film is scratched and damaged, the aluminum itself can be quickly repaired in the air. Compared with the oxide films of zinc, tin, and copper, the aluminum oxide film is not only formed quickly, but also dense and not easy to lose. In this way, aluminum has a good anti-corrosion function.

Recommended Read

Decorative ceilings – a new choice to enhance the beauty and function of the space

Architectural Wire Mesh: Transform Spaces with Modern Metal Aesthetics