Three main characteristics of

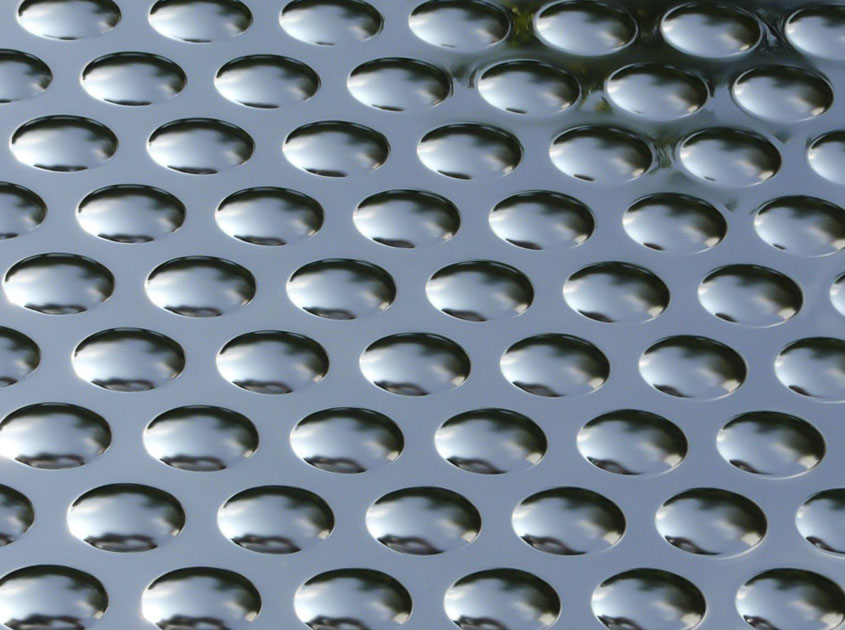

perforated mesh corrosion:

1.Uniform corrosion

The phenomenon that the entire surface of the metal in contact with the corrosive medium is corroded is called uniform corrosion, also called overall corrosion. A kind of surface corrosion, stainless steel has good corrosion resistance, and its uniform corrosion is not large.

2. pitting corrosion

Corrosion concentrated on the local area of the metal surface, and quickly asked internal development, and finally penetrated: When the stainless steel surface contacted with chloride ions, the anion chloride ions were easily adsorbed on individual points on the surface of the steel, destroying the oxide film there. It is easy to cause pitting corrosion. Surface defects of stainless steel are also one of the important causes of pitting corrosion.

3.Intergranular corrosion

When austenitic stainless steel is heated at 450 ° C to 850 ° C, chromium carbides are precipitated from the ten grain boundaries, resulting in the formation of chromium-depleted areas around the grains. Under the action of the corrosive medium, it can penetrate into the metal along the grain boundaries. A type of corrosion that occurs between characters is called intergranular corrosion. This kind of corrosion causes damage when there is any change in the appearance of metal, so it is the most dangerous form of damage of stainless steel.

Recommended

Talk specificall

Types and uses Metal decorative nets intrMay 14, 2021

Introduction of

Curtain wall decoration mesh production pMay 14, 2021

How to design or

Art planning is generally integrated intoMay 14, 2021

Briefly introduc

Decorative metal mesh is made of metal roMay 14, 2021