2020-07-09

Let's first look at the material (including the material of the punch pin and the punched mesh substrate).

Stainless steel is relatively hard. Punch pin fractures mostly occur on the punched stainless steel plate, especially the 201 stainless steel, so we need to follow The characteristics of the harder stainless steel are not only high hardness, wear resistance but also good toughness (usually we use Canaan No. 1 and high-speed steel punches).

Sometimes the design of the mold does not match the punch pin, which will cause the punch pin to break. For example, the punch pin is 60mm long, and the die is 59mm, so that the punch pin grows 1.0mm, the punch pin will be easily broken when the die is working; in another case, the upper and lower die holes of the die are not parallel, which acts on the die In case of force, the punch needle will break the needle.

Recommended Read

Decorative ceilings – a new choice to enhance the beauty and function of the space

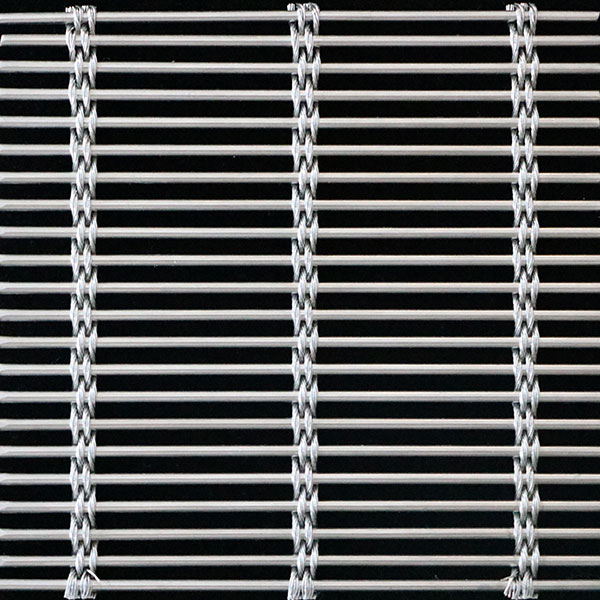

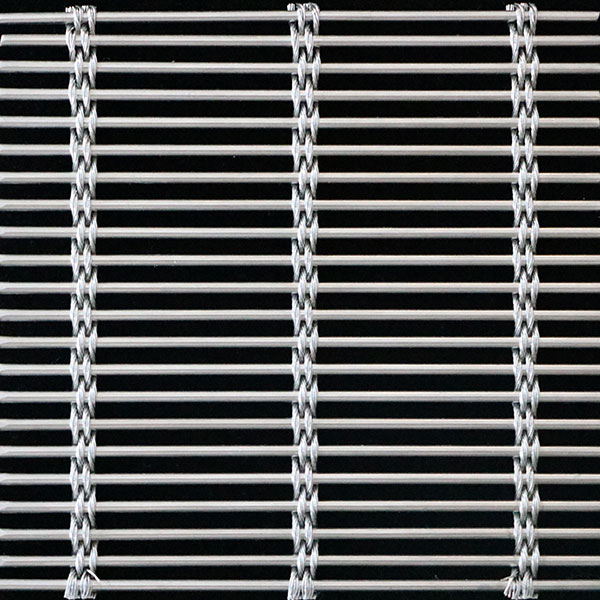

Architectural Wire Mesh: Transform Spaces with Modern Metal Aesthetics