2020-06-22

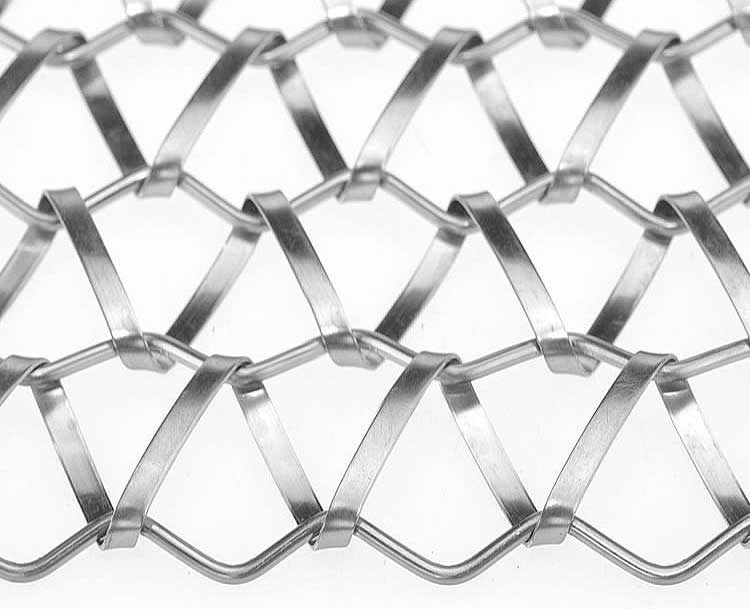

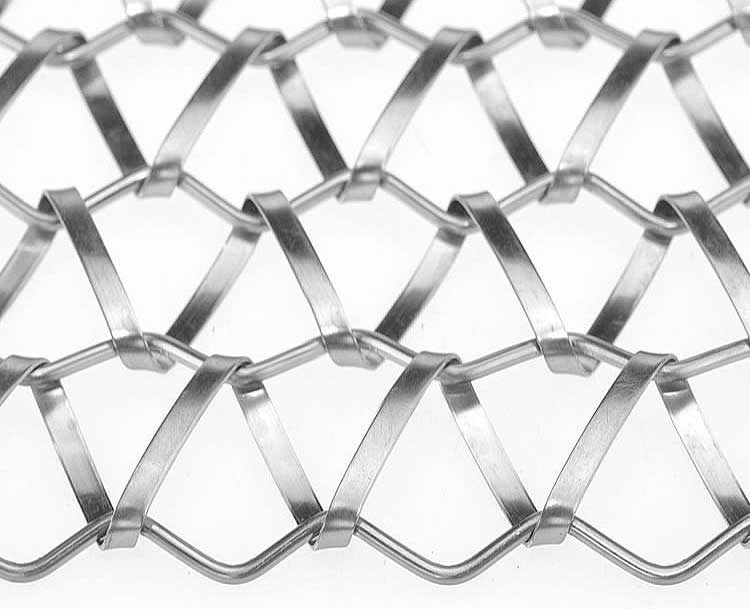

The processing process of stainless steel conveyor belt is mainly divided into the following 6 full processes, each of which is critical. Below we will actually introduce the production process of stainless steel conveyor belt in detail: according to the office environment of the conveyor belt Under the same standard, the raw material requirements for stainless steel wire are different. If the cooling condition only requires that the stainless steel conveyor belt is satisfactory, the raw material of the stainless steel plate can be. Generally, 201 or 301 can be selected. If it is heat-resistant, the raw material of the stainless steel conveyor belt can be selected. 314 is still 316.

What is the production process of stainless steel mesh belt

The specifications and models of stainless steel conveyor belts are customized according to the customer's requirements. When the customer purchases the stainless steel conveyor belt, the customer needs to mark the following parameters of the stainless steel conveyor belt. The pitch diameter, cable diameter, pitch, and string of the stainless steel conveyor belt The wire diameter is finally marked with the length and width of each stainless steel conveyor belt parts.

The general-purpose stainless steel wire for forming stainless steel conveyor belt parts will be required to be processed in the future when the raw materials enter the factory. The machine will be operated and the stainless steel conveyor belt will be formed by wire winding. According to the illustration of the stainless steel conveyor belt, the formed stainless steel conveyor belt wire is extracted to ensure a total width of each stainless steel conveyor belt.

Recommended Read

Decorative ceilings – a new choice to enhance the beauty and function of the space

Architectural Wire Mesh: Transform Spaces with Modern Metal Aesthetics