Metal mesh is widely used in construction and decoration, and different types of metal mesh often use different manufacturing processes. Here are some common types of metal mesh and their manufacturing process:

Net fallen:

Manufacturing process: Welded mesh is typically made of welded metal wires or strips, and the metal materials are joined by electrical welding or other welding methods to form a mesh structure.

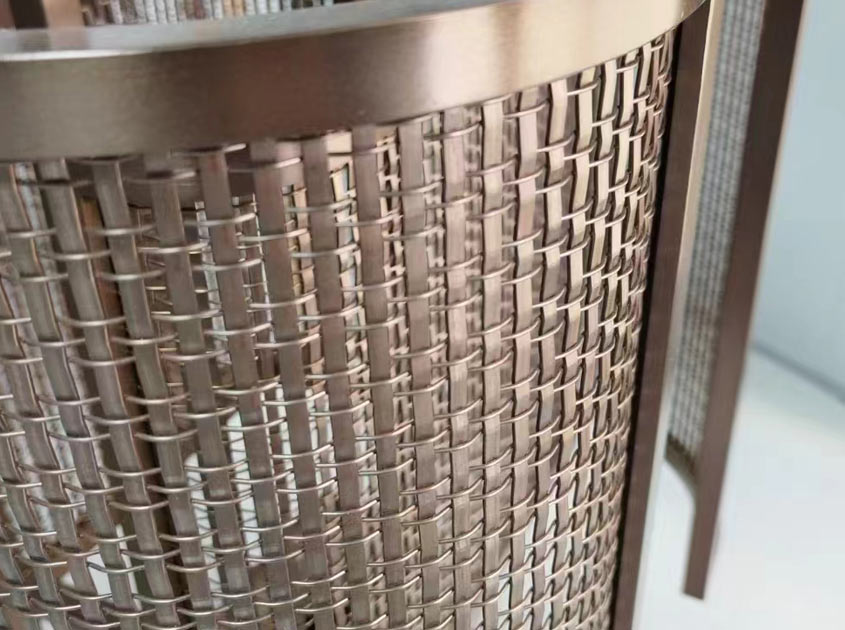

The woven net:

Manufacturing process: Woven mesh is made from metal wires or strips that are interwoven.

Additional net:

Manufacturing process: Expanded mesh is formed by cutting and stretching a metal plate to create mesh holes, usually using a special stretching machine.

A bathing grid:

Manufacturing process: A stamping grid is formed by punching a series of holes in a metal plate to create a grid structure, which usually requires specialized punches and molds to complete.

Laser cut mesh:

Manufacturing process: Laser cutting grid uses laser cutting technology to cut holes of unique shapes in a metal plate to form a grid structure, which has high precision and flexibility.

Welding augmented mesh:

Manufacturing Process: Welded expanded mesh combines welding and expansion processes Usually, metal bars or lines are first welded and then stretched to form a metal mesh with a specific shape.

These manufacturing methods have their own features while manufacturing metal mesh Suitable manufacturing process can be selected according to the application, design requirements and performance requirements of metal mesh to manufacture metal mesh products which have special functions and appearances.

pre:Design and application of architectural decorative nets

next:Maintenance and care methods of architectural decorative metal mesh

© 2025 Joinwin Architectural Wire. All Rights Reserved. | Sitemap

Recommended Read

Luxury Decorative Metal Mesh for Middle Eastern Interiors and Architecture

Mini Chain Link Mesh Curtain – Flexible Metal Drapery with Modern Appeal