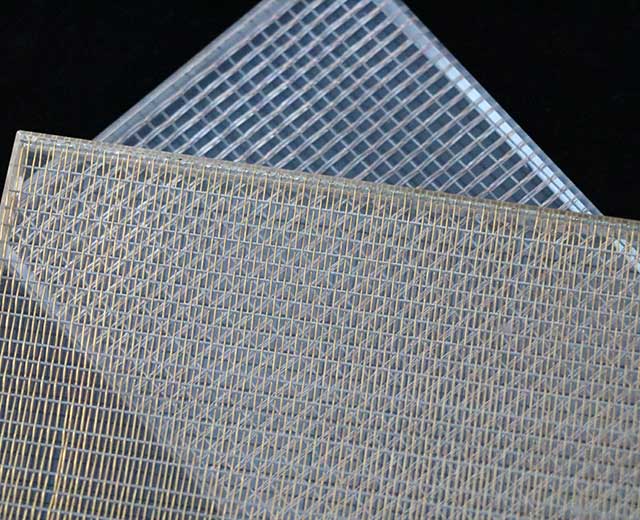

Laminated glass wire mesh, is the combination of high strength glass and refined structure metal mesh.These materials allow the transparency, rigidity and structural qualities when laminated in-between two or more layers of glass. This will give decorative and aesthetic qualities of the metal weaves and meshes.

Today we are going to discuss the adhesive of glass and the inner metal mesh.There are two common adhesives, EVA and PVB.

EVA (ethyl vinyl acetate) is a copolymer adhesive that can adhere to a variety of materials. EVA hot melt adhesives generally do not use water or solvents to acquire their adhesive properties, which allows them to set very quickly, have a long shelf life and perform well in a wide range of temperatures.EVA has a good fluidity under high temperature,thus additional functional layers such as organic to make beautiful decorative glass or functional glass. EVA has good water resistance, but its UV resistance is weak. It is easy to yellow and black in long-term sun exposure, so it is mainly used for indoor partitions.

PVB(Polyvinyl Butyral) Laminated glass is most widely used interlayer.PVB has sound insulation, anti-ultraviolet, can be made into color or high transparent, suitable for exterior decoration.Extra Clear Color and super weathering resisitance.

More information of the laminated glass, welcome to contact Qunkun Metal for further communication.

© 2025 Joinwin Architectural Wire. All Rights Reserved. | Sitemap

Recommended Read

What are the design possibilities with different patterns and weaves of metal mesh

What are the maintenance requirements for Laminated Glass Metal Mesh