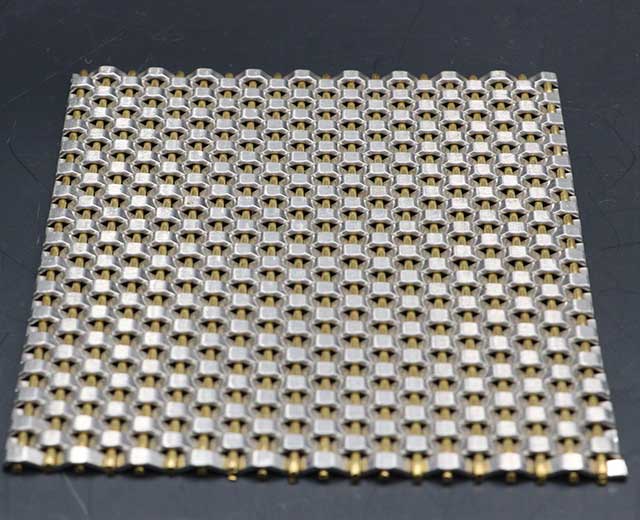

Architectural stainless steel mesh has now become the leader in the conveying industry and is deeply loved by the majority of users. The mesh belt must be properly sprayed during construction. Only in this way can it be better protected. What are the main methods.

Not easy to fall off, long service life. The surface of the construction stainless steel mesh belt must be pretreated before spraying. Paint drying is pided into physical drying and chemical drying according to the nature of the paint itself. The pre-treatment of construction stainless steel mesh is very important, and spraying also requires a process, which is pided into three processes. The predecessors are pretreated first, then sprayed, and finally dried.

There are more than ten kinds of coatings such as grease coatings, natural resins, epoxy resins, phenolic resins, etc., which can be selected according to the actual situation. Drying In order for the coating to be excellent, hard, and wear-resistant, it must be fully dried before use. The pretreatment methods of stainless steel mesh belts of different constructions are different. The spraying methods include manual, automatic, electrostatic, electrophoresis and other methods, which can be selected according to the batch size and shape of the Great Wall mesh belt.

Spraying is based on the variety, function and curing conditions of the coating, and the spraying process and method are also different. Users can choose the shape, size and batch of stainless steel mesh belt. In practice, for quick-drying, solvent-volatile coatings or heat-curing coatings are often used, and ideal results can be achieved by natural drying or a simple drying process.

pre:How to avoid problems in the installation of decorative meta

© 2025 Joinwin Architectural Wire. All Rights Reserved. | Sitemap

Recommended Read

The Beauty of Texture: Architectural Woven Mesh in Interior Wall Panels

The Art of Light Play: Architectural Woven Mesh in Lighting Installations