The surface color of today's stainless steel screens is different from that of general colored products. Generally colored products can be made by spraying or water dyeing, but they are easy to fade and fade in the air or rain.

The difference between stainless steel wire mesh is that its processing technology is electroplated in a vacuum plating environment. The color of the surface is the color of metal ions. Metal ions and iron ions form a charge attraction relationship between the particles. The attraction formed by countless micro-materials makes the ion layer on the surface of the stainless steel screen have a strong adsorption force, so it will not fade or fade. This is the biggest feature of the surface color of the stainless steel screen. The color is very rich. At present, the main colors of our electroplating are: rose gold, black titanium, royal blue, titanium, champagne gold, bronze, etc. Among them, rose gold, black titanium, and titanium are commonly used to make various common colors such as antique furniture and architectural decoration.

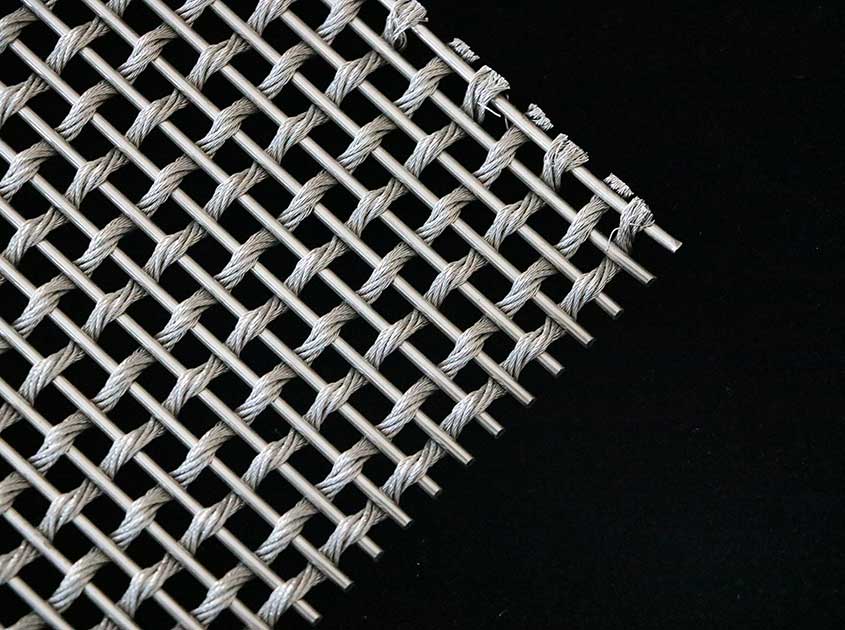

Stainless steel metal screens, as the name suggests, are screens made of stainless steel. The multi-color surface of the stainless steel screen mainly reflects the overall display and the effect of setting off the entire decorative environment, so what are the characteristics of using stainless steel? In fact, before explaining the characteristics of stainless steel, I want to talk about the difference between its color and other products.

As the name implies, the stainless steel metal screen is a kind of steel that will not rust. There are many places used in life. So let us uncover the mystery of stainless steel together. Stainless steel refers to steel that is resistant to weakly corrosive media such as air, steam, and water, and chemically corrosive media such as acids, alkalis, and salts, and is also called stainless acid-resistant steel. Stainless steel will not produce corrosion, pitting, rust or abrasion, has corrosion resistance, enhanced strength, steel deformation is not easy to break and environmental protection performance, and it is not easy to rust. It is suitable for some public environment hardware facilities used in harsh environments (humidity, acid-base and other indoor and outdoor environments). If the surface is painted and colored, the adhesion will be higher, but the corrosion resistance will disappear after use and the surface zinc layer will be damaged.

The stainless steel metal screen is not only durable, but also resistant to dirt. The color stainless steel screen without fingerprint treatment can not only enhance the oxidation resistance of the color stainless steel screen, but also has the characteristics of waterproof and anti-fingerprint. The color stainless steel plates used to make color stainless steel screens can also be used to make various stainless steel doors and stainless steel. Wine racks, stainless steel partitions, etc., not only are not easy to get dirty, but also have better performance. For example, ordinary stainless steel bronze brushed screens and stainless steel rose gold brushed screens can be achieved without leaving fingerprints.

© 2025 Joinwin Architectural Wire. All Rights Reserved. | Sitemap

Recommended Read

Transforming Interiors: Architectural Woven Mesh in Ceiling and Wall Applications

Architectural Woven Mesh: A Solution for Artistic Ceiling Installations